The 3 pin flasher relay is a 12V electronic unit designed for automotive turn signal systems, compatible with both LED and filament-type bulbs up to 180W. It features a solid-state design, ensuring reliable operation and low power consumption, with terminals labeled for specific functions: 31 to Earth, 49 to Supply, and 49a for additional configurations. This relay is ideal for vehicles requiring efficient and consistent turn signal functionality, including motorcycles and classic cars, while also supporting hazard flasher systems. Its compact size and durable construction make it a versatile solution for various wiring setups.

Overview of the Flasher Relay and Its Function

A 3 pin flasher relay is an electronic component designed to control turn signal and hazard light systems in vehicles. It operates by interrupting the electrical circuit at a specific frequency, creating the flashing effect required for turn signals. The relay consists of three terminals: X (power input), L (load), and P (pilot/dash indicator). This solid-state design ensures reliability and efficiency, supporting both LED and filament-type bulbs up to 180W or 15A at 12V. The relay produces a familiar clicking sound during operation, indicating proper function. Its compact size and durability make it suitable for various automotive applications, including motorcycles and classic vehicles.

Key Components and Terminology

The 3 pin flasher relay consists of three essential terminals: X (power input), L (load), and P (pilot/dash indicator). These terminals are labeled to ensure correct wiring connections. The relay operates on a 12V system, supporting both LED and filament-type bulbs. Key components include a solid-state electronic circuit, which ensures efficient and reliable operation. Terminology such as “dash indicator” refers to the dashboard light that signals turn signal activation. The relay’s design ensures compatibility with various automotive systems, including hazard flashers and towing setups, making it a versatile component for vehicle wiring applications.

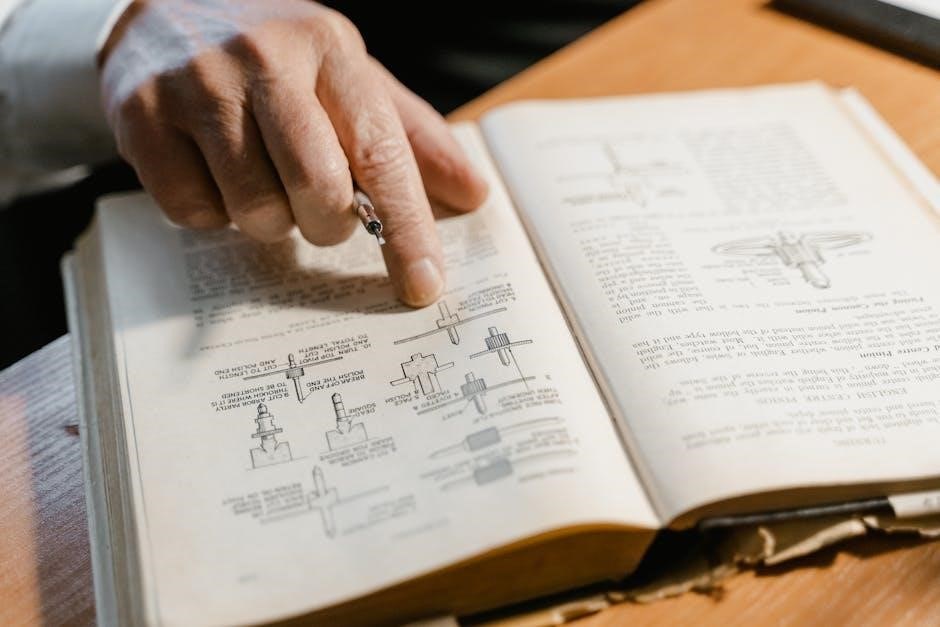

Understanding the Wiring Diagram

The wiring diagram illustrates the 3 pin flasher relay’s connections, with terminals labeled for power input, load, and dash indicator. It guides proper installation and wiring.

Terminal Configuration and Labels

The 3 pin flasher relay features terminals labeled for specific functions. Terminal 31 is connected to Earth (ground), while terminal 49 receives the power supply from the battery. Terminal 49a, if present, may be used for additional configurations or hazard flasher systems. Other common labels include P (dash indicator), L (turn signal switch), and X (hazard flasher switch). Proper identification and connection of these terminals are crucial for correct operation. Misconnecting terminals can lead to malfunctions or electrical issues. Always refer to the wiring diagram for accurate terminal assignments and ensure all connections are secure to maintain reliable operation of the turn signal system.

How to Read the Wiring Diagram

Reading a 3 pin flasher relay wiring diagram begins by identifying the components and their symbols. Locate the relay, represented as a rectangular box with terminal labels. Trace the wires from the power source (battery) to terminal 49, then to the load (turn signal switch) on terminal L, and finally to the dash indicator on terminal P. Ground connections are typically indicated by a downward-pointing arrow or “GND” label. Pay attention to color codes for wire identification. Start from the positive power source and follow the circuit through each component, ensuring all connections align with the diagram. This methodical approach ensures accurate wiring and proper relay function. Always cross-reference the diagram with your vehicle’s specific setup for precise connections and to avoid electrical issues.

Common Symbols and Representations

In a 3 pin flasher relay wiring diagram, common symbols include the battery represented by a “+” sign and ground indicated by a downward-pointing arrow or “GND.” Terminals are labeled as P (dash indicator), L (turn signal switch), and X (hazard flasher switch). Wires are often color-coded, with colors like red for power, yellow for turn signals, and green for hazards. Dashed lines may represent connections to external components. Solid lines indicate direct wiring paths. These symbols simplify the diagram, making it easier to trace circuits and identify connections. Understanding these representations is key to interpreting the wiring layout accurately and efficiently.

Installation Steps

Begin by preparing the relay, ensuring terminals are clean and correctly labeled. Connect wires to the appropriate pins, following the diagram for P, L, and X assignments. Secure all connections firmly before testing the system to ensure proper functionality and safety.

Preparing the Relay for Installation

Before installation, ensure the relay is compatible with your vehicle’s voltage and wiring system. Locate the terminals labeled 31 (Earth), 49 (Supply), and 49a (if applicable). Clean the terminals to ensure good conductivity and verify the relay’s orientation matches the wiring diagram. Secure the relay in an accessible location, away from heat sources, using mounting clips or brackets. Connect terminal 31 to a reliable ground point and terminal 49 to the 12V power supply, preferably through a fuse. For terminal 49a, refer to the diagram for specific configurations. Use appropriate gauge wires to prevent voltage drop and ensure all connections are secure. Double-check the wiring diagram for your vehicle to confirm the correct pin assignments and avoid mismatches;

Connecting the Wires to the Relay

Connect terminal 31 to a reliable ground point on the vehicle chassis. Terminal 49 should be linked to the 12V power supply, typically from the battery or a fused circuit. If your relay has a terminal 49a, connect it to the turn signal switch or hazard flasher switch, as indicated in the wiring diagram. The terminal labeled L connects to the turn signal switch, while P connects to the dash indicator bulb and then to ground. Terminal X links to the hazard flasher switch. Use appropriate wire gauges and ensure all connections are secure and properly insulated to prevent short circuits. Always consult the wiring diagram for specific configurations and test the connections before powering the system.

Testing the Installation

After connecting the wires, turn the ignition switch to the “on” position and test the turn signals and hazard lights. Activate the turn signals one at a time to ensure they flash correctly and consistently. Check the dash indicator bulb for proper illumination. Test the hazard switch to verify all turn signals flash simultaneously. Listen for the familiar clicking sound of the relay during operation. Ensure no blown fuses or short circuits occur during testing. If the signals malfunction or the dash light does not illuminate, recheck all connections for accuracy and consult the wiring diagram to identify potential issues. Proper testing ensures reliable operation and safety on the road.

Troubleshooting Common Issues

Identify faulty connections by checking terminal labels and ensuring proper wiring. Common malfunctions include no signal flashing, incorrect bulb illumination, or relay failure. Verify connections and test components to isolate issues. Consult the wiring diagram to trace signal paths and confirm terminal assignments. Replace damaged or corroded wires and ensure all terminals are securely connected. If issues persist, consider replacing the relay or checking for blown fuses in the circuit. Proper troubleshooting ensures reliable operation and extends the lifespan of the system.

Identifying Faulty Connections

Start by examining the wiring diagram to verify terminal connections. Check for loose or corroded wires, especially at terminals P (dash indicator), L (turn signal switch), and X (hazard flasher switch). Ensure power supply (terminal 49) and ground (terminal 31) are connected correctly. Use a multimeter to test for continuity or short circuits; If the relay fails to click, suspect a faulty ground or power supply issue. Incorrect wiring, such as reversed terminals, can cause malfunction. Visually inspect for damaged insulation or frayed wires that may disrupt the circuit. Addressing these issues promptly prevents further electrical damage and ensures proper operation.

Resolving Common Malfunctions

Begin by reviewing the wiring diagram to identify potential issue sources. If the turn signals fail to flash, check the relay’s power supply (terminal 49) and ground connection (terminal 31). Verify that the turn signal switch (terminal L) and hazard switch (terminal X) are functioning properly. For LED compatibility, ensure the relay supports low-wattage circuits. If the relay produces no clicking sound, replace it immediately. Correct any reversed or loose connections, and replace damaged wires. Testing each component systematically ensures quick resolution and prevents further system damage, restoring proper signal functionality efficiently and safely.

Upgrading to a 3 Pin Flasher Relay

Upgrading to a 3 pin flasher relay enhances reliability and compatibility, especially with LED setups, reducing signal failures and ensuring consistent operation in various automotive applications.

Benefits of Using a 3 Pin Relay

The 3 pin relay offers enhanced functionality, supporting both LED and filament bulbs up to 180W, with low power consumption and minimal heat generation. Its solid-state design ensures quiet operation and longevity, eliminating the mechanical noise of thermal flashers. The relay’s compact size simplifies installation, while its clear terminal labeling facilitates wiring. It supports hazard flasher systems and is compatible with various vehicles, including motorcycles and classic cars. This versatility makes it an ideal choice for modern and retro automotive applications, providing reliable and consistent turn signal functionality. Its durability and efficiency ensure long-lasting performance in diverse electrical systems.

Installation Tips for an Upgrade

When upgrading to a 3 pin flasher relay, ensure compatibility with your vehicle’s electrical system, especially if switching from a 2-pin relay. Disconnect the battery to avoid electrical shocks. Use a wiring diagram to identify terminals accurately. Mount the relay securely to prevent vibration damage and ensure proper heat dissipation. Connect terminals correctly: 31 to Earth, 49 to the power supply, and 49a if required. Test the system post-installation to confirm functionality. Avoid using damaged wires or connectors to prevent malfunctions. Consider consulting a professional if unsure about the process. Proper installation ensures reliable operation and longevity of the relay.

Applications and Compatibility

The 3 pin flasher relay is widely used in automotive systems, including turn signals and hazard lights. It supports LED and filament-type bulbs, making it versatile for 12V vehicles. Compatible with motorcycles, classic cars, and specialty vehicles, it ensures reliable operation across various wiring setups.

Automotive Applications

The 3 pin flasher relay is primarily used in automotive systems to control turn signals and hazard lights. Its compact design and efficient operation make it ideal for various vehicles, including cars, trucks, and motorcycles. Compatible with both LED and filament-type bulbs, it ensures consistent flashing rates and minimal power consumption. Common applications include standard turn signal systems, emergency hazard lighting, and specialty vehicles requiring reliable indicator functionality. Its versatility also extends to classic cars and custom wiring setups, where maintaining original aesthetics while improving performance is essential; This relay is a crucial component for any vehicle needing a dependable turn signal solution.

Motorcycle and Specialty Vehicle Compatibility

The 3 pin flasher relay is widely compatible with motorcycles and specialty vehicles, offering reliable turn signal and hazard light functionality. Its compact size and low power draw make it ideal for motorcycles, including classic models like Triumph and Defender. Designed to work with both LED and filament-type bulbs, it ensures consistent performance across various lighting setups. Specialty vehicles, such as custom bikes or vintage cars, benefit from its versatile wiring options and durable construction. This relay is a popular choice for maintaining or upgrading indicator systems in unique and performance-oriented vehicles, ensuring safety and visibility on the road.

Safety and Best Practices

Always disconnect the battery before working with electrical systems to prevent shocks or short circuits. Use proper tools and follow the wiring diagram carefully to ensure connections are secure and correct, avoiding potential malfunctions or hazards. Regularly inspect wires and terminals for damage or corrosion to maintain system reliability and safety. Additionally, ensure the relay is rated for the vehicle’s electrical system to prevent overheating or failure. Proper installation and maintenance are crucial for reliable operation and safety of the 3 pin flasher relay system in any vehicle.

Safety Precautions When Working with Electrical Systems

When working with the 3 pin flasher relay, always disconnect the battery to prevent electrical shocks or short circuits. Ensure the vehicle is in park with the ignition off. Wear protective gear like gloves and safety glasses. Avoid touching live wires, and use insulated tools to handle connections. Never bypass safety features or ignore warning signs, as this could lead to system damage or personal injury. Properly ground components to prevent unintended power surges. Following these precautions ensures a safe working environment and protects both the technician and the vehicle’s electrical system from potential hazards during installation or repair.

Best Practices for Wiring

When installing a 3 pin flasher relay, ensure all connections are clean and secure to prevent voltage drops or intermittent faults. Use the correct gauge wire for the application to handle the current load safely. Label wires clearly to avoid confusion during future maintenance. Route wires away from heat sources and moving components to prevent damage. Follow the wiring diagram precisely, matching terminals correctly (e.g., X for power, L for the turn signal switch, and P for the dash indicator). Regularly inspect wires for signs of wear or corrosion and replace them as needed to maintain reliable operation and safety.